No products in the cart.

Return To Shop

0

0

Shopping cart (0)

Subtotal: CAD $0.00

Spend CAD $200.00 to get free shipping

Congratulations! You've got free shipping.

0

0

No products in the cart.

Return To Shop

Shopping cart (0)

Subtotal: CAD $0.00

Spend CAD $200.00 to get free shipping

Congratulations! You've got free shipping.

About Vanilla

Know More About Vanilla Beans - SortingWarmingSteamingDryingRefininggradingstorage

Green Vanilla Sorting

The first step involves sorting the freshly harvested green vanilla beans. During this process, any beans that are overripe or showing signs of rot are carefully separated from the rest.

Warming (1-3 mins) Temperature: 60-70°C

To kickstart the enzymatic process, the sorted green vanilla beans are placed in baskets and submerged in warm water. This step is carried out in traditional settings, ensuring that the vanilla begins its transformation under controlled conditions.

Steaming (12-72 hours)

Immediately after warming, the beans are placed in wooden boxes and covered with cotton blankets. The heat from the previous step is retained, allowing the vanilla to steam gently. Multiple baskets of beans are often stacked in each box, and the boxes are sealed to maintain the heat.

Drying in the Sun (45-90 mins)

After the steaming process, the vanilla beans are spread out on cotton blankets to dry under the sun. This exposure to sunlight helps reduce moisture content and further develops the flavor.

Steaming Under Cover (10-21 days)

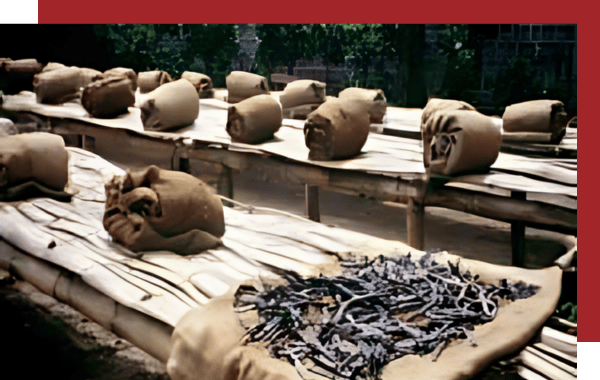

After sun drying, the vanilla beans are wrapped up in the blankets, which are then rolled and oiled to trap heat. The beans are left in this state overnight and unrolled the next day for more sun exposure. This process is repeated daily as weather permits, gradually reducing the moisture content.

Sun Sorting

The vanilla pods are sorted once more under the sun. Fully dried pods are removed from the blankets, while those still needing drying are left out longer. This is done repeatedly until all the pods have reached the desired dryness.

Drying in the Shade (10-15 days)

The semi-dried vanilla pods are transferred to ventilated indoor spaces where they are placed on sieves to continue drying. They are then bundled into small groups and placed on shelves to complete the drying process. The length of this phase depends on the remaining moisture in the pods.

Sorting & Classification

After drying, the vanilla pods are sorted by type (split or whole) and quality. This step ensures that each pod is correctly categorized before moving on to the refining stage.

Refining (20-80 days)

To further enhance the vanilla’s aroma, the pods are placed in boxes, wrapped in wax paper, and undergo a refining process. During this time, the pods are regularly inspected for scent and appearance. Any pods with imperfections are reprocessed and reintegrated once they meet the required standards.

Measurement & Bundling

Once the initial refinement is complete, the vanilla pods are measured again to ensure consistency in length and quality. They are then bundled according to these criteria.

Second Refining & Grading (20-40 days)

The bundles are wrapped in wax paper and placed in boxes for a second round of refining. Regular inspections are carried out every 10 to 15 days to monitor quality. After this stage, the vanilla is graded and packed into wooden and metal boxes based on length and quality.

Storage & Olfactory Control

The metal boxes, each containing around 6 kg of vanilla, continue the refinement process during storage. The beans are regularly inspected to ensure they have stabilized and are ready for export or extraction.

Marking, Sampling, and Quality Analysis

Each box is labeled with specific details such as number, mark, lot, and article for traceability. Samples are taken for internal analysis, where humidity and vanillin content are checked. Additional quality and phytosanitary controls are performed to ensure the vanilla meets all standards.

Stable Storage

Once the vanilla has passed all olfactory and visual inspections and is deemed stable, it is ready for export or direct extraction, with no further changes expected under normal storage conditions.